The Duty of a Transformer Oil Regeneration Plant in Modern Industry

Exactly How Regenerated Transformer Oil Extends Transformer Life Expectancy

The function of transformer oil is critical in ensuring the dependability and long life of transformers, serving as both an insulator and coolant. Regrowed transformer oil offers a compelling option to enhance these functions by properly removing damaging impurities that compromise efficiency.

Significance of Transformer Oil

Transformer oil plays a crucial role in the efficient operation of electric transformers. It mainly works as a protecting tool, avoiding electric discharges and ensuring that components run securely under high voltage problems. The oil's dielectric buildings are essential to maintaining the integrity of the transformer, as they reduce the threat of failures that could cause disastrous events or pricey downtimes.

Along with its protecting capacities, transformer oil also works as a coolant. As transformers run, they generate heat that should be dissipated to avoid getting too hot and succeeding damage. The oil circulates within the transformer, soaking up and transferring warmth away from critical elements, thus keeping ideal operating temperature levels.

Additionally, transformer oil serves as an obstacle against dampness and pollutants, which can endanger the performance and longevity of the transformer. Its chemical residential or commercial properties aid in reducing the effects of acids and various other byproducts that might form with time, adding to the total health of the electrical system.

Advantages of Regenerated Oil

Furthermore, regenerated transformer oil has a reduced degree of impurities, including bits and impurities that can degrade performance. This purity not just enhances the oil's thermal conductivity but also extends the operational life-span of transformers by minimizing overheating dangers. The enhanced thermal stability of restored oil ensures consistent performance even under high operating temperatures, which is crucial for maintaining transformer performance.

An additional advantage is its ecological influence. Restored oil advertises sustainability by reducing waste and the need for new oil production, thus decreasing the carbon footprint connected with transformer upkeep. Transformer Oil Regeneration. The longevity of regenerated oil translates to lower upkeep expenses over time, as fewer oil changes and much less constant devices downtime are needed.

Process of Oil Regrowth

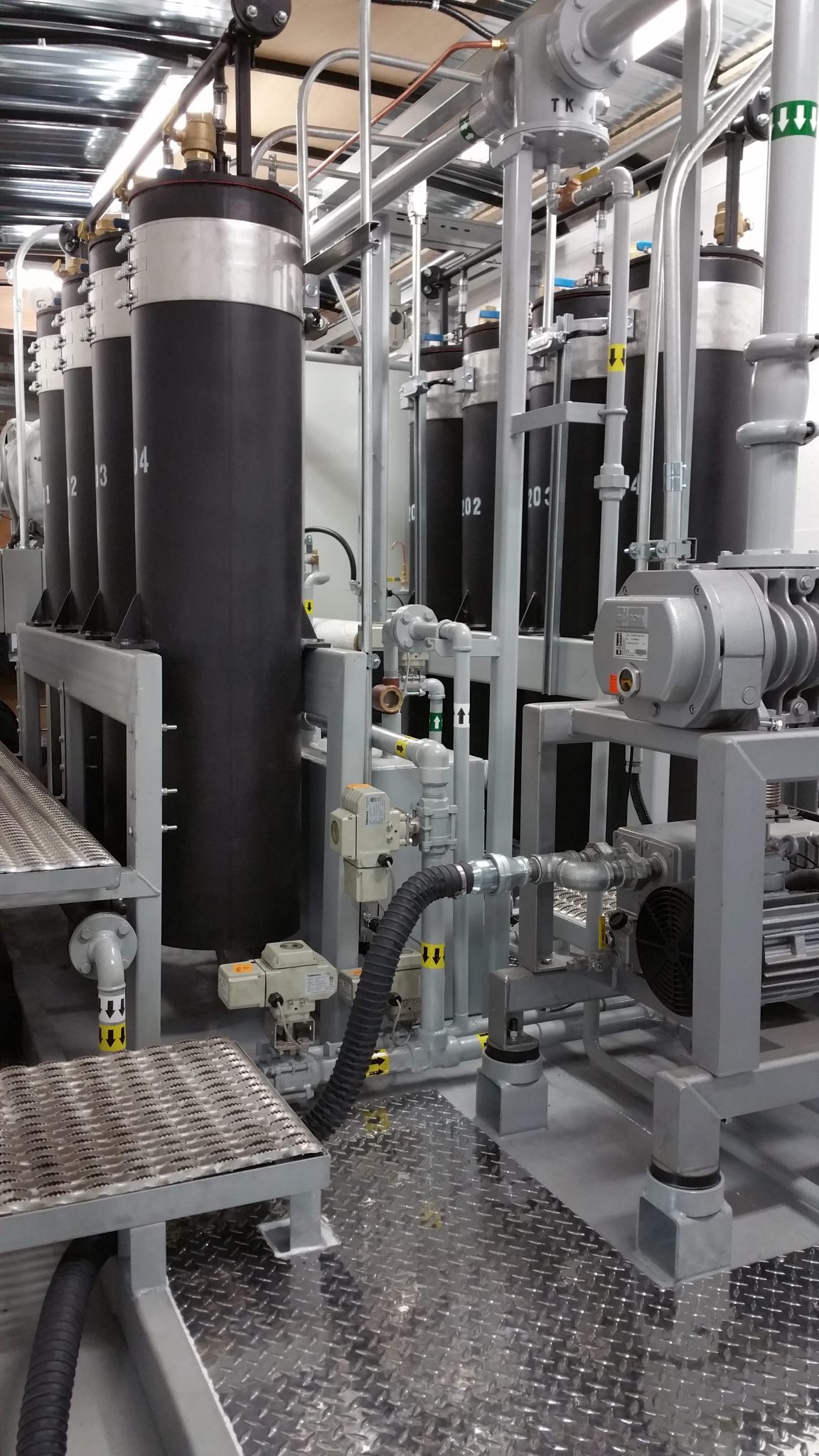

The regrowth of transformer oil includes a systematic procedure created to bring back the oil's original homes and enhance its efficiency. This process generally starts with the elimination of the utilized oil from the transformer, which is after that based on various filtration methods.

The first action in the regeneration procedure is the filtering, where solid pollutants such as steel, sludge, and dirt particles are removed. This is typically adhered to by vacuum purification, which assists to get rid of wetness and volatile substances, consequently improving the oil's dielectric toughness.

Influence On Transformer Efficiency

Restoring the buildings of regenerated transformer oil considerably affects the overall efficiency of transformers. Boosted dielectric stamina is among the most important advantages, as it allows for much better insulation and reduces the probability of electric breakdown. This enhancement leads to an extra stable operation under high voltage problems, inevitably leading to enhanced effectiveness.

In addition, the removal of impurities and degradation products during Click This Link the regeneration procedure lessens the threat of overheating. Cleaner oil assists in far better warmth dissipation, which is essential for maintaining optimal operating temperature levels. Consequently, the thermal efficiency of the transformer is improved, enabling higher loads without compromising reliability.

Moreover, the chemical security of regenerated oil makes certain long term operational life. It resists oxidation and deterioration, lowering the regularity of upkeep treatments and oil substitute. This stability not only contributes to enhanced efficiency yet additionally straightens with sustainability objectives by lessening waste.

Future of Transformer Maintenance

As developments in technology remain to improve the landscape of electric engineering, the future of transformer maintenance is positioned for substantial improvement. The combination of smart technologies, such as IoT sensing units and anticipating analytics, enables real-time monitoring of transformer wellness, improving the capacity to preemptively deal with issues prior to they intensify into significant failures. This proactive strategy not only makes best use of functional efficiency but additionally prolongs the lifespan of transformers.

In addition, the application of expert system (AI) in information analysis permits more exact fault discovery and medical diagnosis. By leveraging artificial intelligence algorithms, upkeep teams can recognize patterns in operational information that human analysts might neglect, leading to even more informed decision-making.

In addition, the adoption of environment-friendly techniques, including using regenerated transformer oil, is established to redefine maintenance procedures. This lasting approach not only lessens ecological impact however likewise improves the overall health and wellness of the transformer.

Last but not least, the shift towards automation in maintenance procedures is anticipated to streamline operations, decrease downtime, and reduced prices. As these developments remain to progress, the future of transformer upkeep will undoubtedly become much more effective, trustworthy, and lasting, ensuring the integrity of crucial electrical facilities.

Final Thought

The utilization of regenerated transformer oil dramatically boosts the functional long life of transformers. Ultimately, the fostering of restored oil represents a pivotal advancement in transformer upkeep, making sure check my source optimal efficiency and sustainability in the administration of electrical framework.

The function of transformer Read Full Article oil is crucial in ensuring the integrity and durability of transformers, offering as both an insulator and coolant.Transformer oil plays a vital function in the reliable procedure of electrical transformers. Restored oil promotes sustainability by reducing waste and the demand for new oil manufacturing, consequently decreasing the carbon impact connected with transformer maintenance.Recovering the properties of regenerated transformer oil dramatically influences the total efficiency of transformers.The use of regenerated transformer oil significantly boosts the operational long life of transformers.